Product Zone

Our Philosophy...

Rolt strive to manufacture equipment that will meet the requirements of our clients, we listen and dedicate our designs around your needs, to deliver a product that’s easy to use and will run first time every time, print after print.

If you feel that you need something special contact us and we will deliver!

Product Detail

Key Features

Below are the standard key features of a Rolt Dryers.

-

๏The Rolt tower dryers save a great amount of space.

-

๏The material is held to a vertical conveyor and it is therefore possible to use powerful jet blast air drying among other methods

-

๏Heater power is regulated with ‘proportional integrating, differentiating’ heat control, which ensures a steady flow of drying air at the set-point temperature.

-

๏A proportion of the hot air is recirculated.

-

๏The towers can be fitted with web tracking equipment which enable the dryer to run thin substrates.

-

๏The dryer has independent speed controls, so the drying can be matched to conditions – the rest of the machine automatically adjusting to keep pace with it.

-

๏Different jet boxes provide for hot air drying as well as for cold air conditioning of the material. A cooling section can be provided to reduce the heat retained by the material.

-

๏All the dryers have features for economy, can be used in multiples and have different arrangements for heating and flow.

-

๏Back heat, front heat, regulation by solvent evaporation, IR, and baking oven versions are all standard options.

-

๏All the dryers can be fitted with UV or IR.

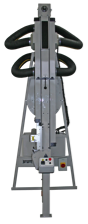

Turbulent Hot Air Dryer

THD-II A low temperature dryer up to 90°C.

THD-II Tall A longer exposure version of the same temperature.

Product Overview

Designed for all 'ROLT' roll-feed presses and others . It will dry all normal roll printed inks at up to 20 meters per minute.

The dryer has a vertical conveyor and is fitted with 6Kw of heat as standard. The heater power is regulated with 'proportional integrating, differentiating' heat control, which ensures a steady flow of drying air at the set-point temperature.

The set-point adjusts from ambient to 100 C, enabling it to cope with high-speed drying of the trickiest jobs. The dryer is separated from the printer by a loop, so the hot air from the drying does not affect the ink in the screens. A jet box provides for hot air and cold conditioning. A proportion of the air is recirculated and a 130mm diameter solvent exhaust to the factory is supplied. The dryer has an independent speed control, so the drying may be matched tot he conditions, the rest of the printing machine automatically adjusting to keep pace with it.